-

Drehschleifring

-

Kapsel-Schleifring

-

Signal-Schleifringe

-

Faser-Optikdrehgelenk

-

Hochfrequenzschleifringe

-

Durch Loch-Schleifring

-

Unterschiedlicher Schleifring

-

Pfannkuchen-Schleifring

-

Hohe gegenwärtige Schleifringe

-

Beleg Ring Components

-

Nicht Mercury Slip Ring

-

Pneumatische hydraulische Drehgelenke

-

Integrierter Schleifring

-

Beleg Ring Solutions

-

WilliamJINPAT-Schleifringauftritt ist gut und sorgfältig verpackt, Service-Begeisterung, Bedarf, wieder zu kommen

WilliamJINPAT-Schleifringauftritt ist gut und sorgfältig verpackt, Service-Begeisterung, Bedarf, wieder zu kommen -

MartinSchnelle Lieferung, gute Leistung und gute Qualität, vorwärts schauend zur folgenden Zusammenarbeit.

MartinSchnelle Lieferung, gute Leistung und gute Qualität, vorwärts schauend zur folgenden Zusammenarbeit.

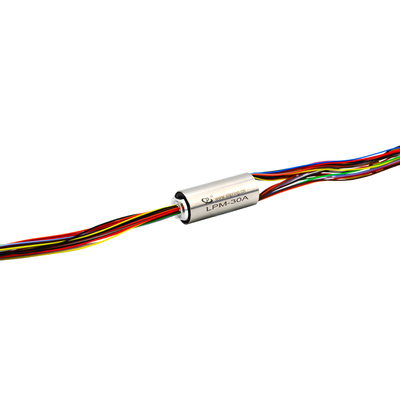

30 Schaltkreis 300 RPM Kapselrutschring 240VAC 1A für medizinische Geräte

Treten Sie mit mir für freie Proben und Kupons in Verbindung.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skypen: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

x| Schaltungsnummer | 30 | Aktuelle Bewertung | 1a |

|---|---|---|---|

| Stromspannung | 240 VAC | Arbeitsgeschwindigkeit | 0 bis 300 U/min |

| Arbeitstemperatur | -20~+60℃ | Elektrisches Geräusch | ≤15mΩ |

| Kontaktmaterial | Edelmetall | Drahtgröße | 30# silberplattierte Kupfer ul, Teflon |

| Bleidrahtlänge | Rotor: 250mm; Ständer: 250mm | Luftfeuchtigkeit | ≤60%RH |

| Schutznote | IP54 | Stil | Kapsel-Schleifring |

| Typ | elektronische Zusätze | Kontaktschnittstelle | Goldkontakte |

| Farbe des Drahtes | Farbunterlegt | ||

| Hervorheben | 30 Schaltkreis Kapselrutschring,300 RPM medizinischer Rutschring,240VAC 1A Kapselrutschring |

||

| Parameter | Wert |

|---|---|

| Schaltungen | 30 |

| Aktuelle Bewertung | 1a |

| Stromspannung | 240 VAC |

| Elektrisches Geräusch | ≤ 15 mΩ |

| Arbeitsgeschwindigkeit | 0 ~ 300 U / min |

| Kontaktmaterial | Edelmetall |

| Drahtgröße | 30# silberplattierte Kupfer ul, Teflon |

| Bleidrahtlänge | Rotor: 250 mm; Stator: 250 mm |

| Arbeitstemperatur | -20 ~+60 ℃ |

| Luftfeuchtigkeit | ≤ 60%relat |

| Schutznote | IP54 |

- Elektrische Geräte und Steuerungssysteme

- Medizinische Einrichtungen und Ausrüstung

- Industriemaschinerie und Automatisierung

- LED -Anzeige- und Beleuchtungssysteme

- Prozesssteuerungsausrüstung

- 12.000 Quadratmeter -Produktionsanlagen mit mehr als 500 Mitarbeitern

- Als nationales Hoch- und neues Technologieunternehmen mit 69 Patenten anerkannt

- Globale Partnerschaften mit renommierten Unternehmen und weltweiten Agenten

- Über 10.000 erfolgreiche Entwürfe für zivile, militärische, gewerbliche und industrielle Anwendungen

- Gegründet 1996 mit mehr als 20 Jahren Produktion und F & E -Erfahrung

- Custom Slip Ring -Lösungen, die auf bestimmte Geräteanforderungen zugeschnitten sind

- Effiziente Produktion und schnelle Lieferfunktionen

Was machen wir?

Wir sind spezialisiert auf die Entwicklung, Gestaltung und Herstellung hochwertiger Schlupfringe und bieten umfassende Lösungen für rotierende Systeme an.

Was ist ein Schlupfring?

Ein elektromechanisches Gerät, das Strom- und Signalübertragung zwischen stationären und rotierenden Strukturen ermöglicht, wodurch schadengefängliche Kabel beseitigt und gleichzeitig die mechanische Leistung verbessert werden.

Produktangebote:

- Elektroschadenringe (Kapsel, Durchlebende, Miniatur)

- Signalschlupfringe (USB, Glasfaser, Hochfrequenz)

- Pneumatische/hydraulische Rotationsgewerkschaften

- Benutzerdefinierte Schlupfringlösungen

- Produktionsfähigkeiten großer Volumen

Wie wähle ich einen Schlupfring aus?

Berücksichtigen Sie die Betriebsparameter Ihrer Anwendung, einschließlich Schaltungszahl, Spannung/Stromanforderungen, Betriebsgeschwindigkeit und Montagekonfiguration. Unsere Ingenieure können bei der Auswahl helfen.

Benutzerdefinierte Lösungen verfügbar?

Ja, unser Engineering -Team entwickelt maßgeschneiderte Lösungen, um bestimmte Anwendungsanforderungen zu erfüllen. Kontaktieren Sie uns, um Ihre Bedürfnisse zu besprechen.

Gesamtbewertung

Rating Snapshot

The following is the distribution of all ratingsAll Reviews